One of the recurring WHS items that QRMC has been identifying with its clients over the last year or so relates to the ongoing compliance of installed pallet racking. What we are generally seeing is a “set and forget” situation whereby, following installation, there are no further checks, inspections or overarching governance to maintain a safe system of work.

In Australia, pallet racking is regulated by the recently updated Australian Standard 4084:2023 Steel Storage Racking. The overarching objective of this Standard is to provide the basis for these storage systems to be designed, installed, used and maintained in a safe manner. Given the frequent interaction with the pallet racking by forklifts and heavy loads, the risk of collision resulting in damage and/or compromise of the racking’s structural integrity is not insignificant.

So, what are the main requirements of AS 4084 and how can these be met?

- Design and Installation

- Compliance: The design and installation of pallet racking systems must comply with the requirements of Australian Standard AS 4084 for steel storage racking.

- Professional Installation: Racking must be installed by a competent person or a certified professional (usually the Racking Manufacturer or Installer) to ensure structural integrity.

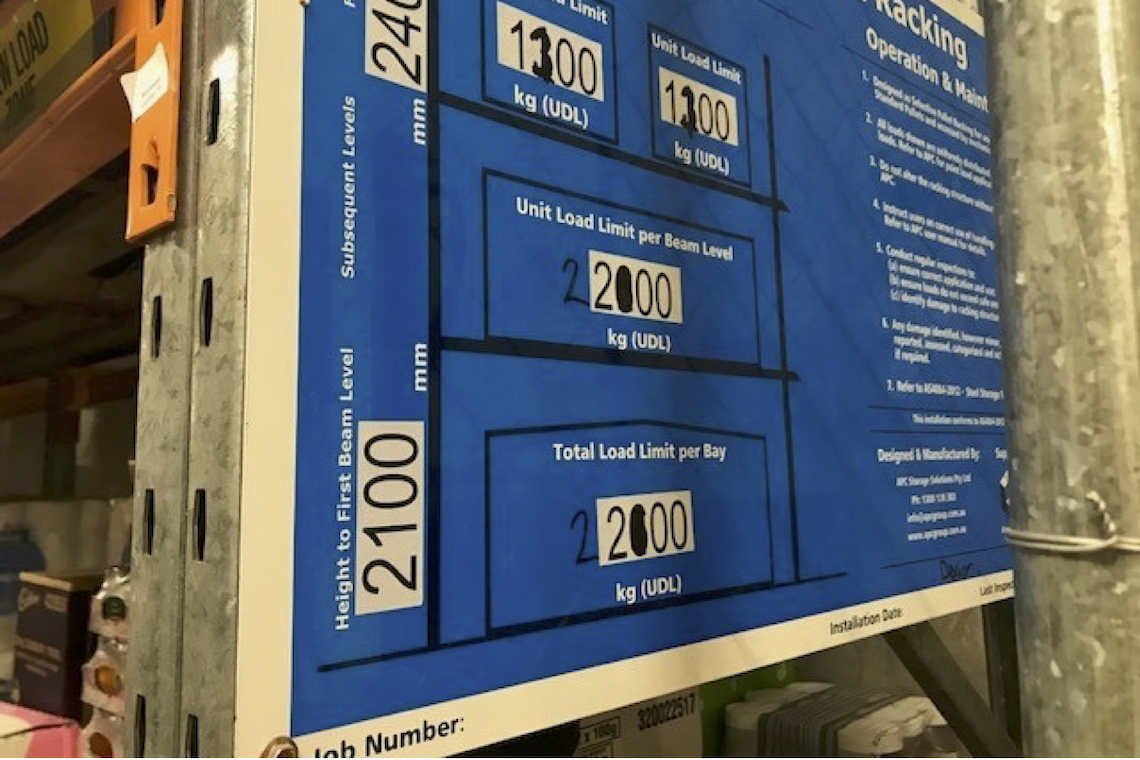

- Safe Load Limits: Must be clearly displayed on all racking systems. Note that different levels within the vertical structure of the racking may have different load limits.

- Emergency Procedures: Develop and communicate emergency procedures in case of racking collapse or other incidents.

- Inspection and Maintenance

- Regular Inspections: Conduct regular inspections for surface damage, wear, and in particular, missing bolts and screws – including dynabolts from the racking into the ground level concrete. Inspections should be more frequent in high-usage areas. As per the emergency processes, areas of significant damage should be cordoned off, signed as out of service, and referred to the manufacturer (or competent service provider) for assessment and repair/replacement.

- Annual Inspections: Must be performed by a competent person (usually the racking installer) who performs a more extensive assessment of the racking, particularly looking at any damage that has the potential to impact its structural integrity.

- Documentation: Keep records of all inspections, maintenance, and repairs.

- Training and Supervision

- Staff Training: Ensure that all employees who use or work near racking systems are properly trained on safe use, loading/unloading processes including load distribution and emergency procedures.

- Supervision: Supervise loading and unloading activities to prevent overloading and ensure safe practices are followed.

- Use

- Check pallet racking integrity prior to use.

- Check loads at height are secure.

- Report all contact and damage issues to the relevant Manager for follow up and actioning – isolate the area if necessary.

By following the requirements of AS 4084 you will ensure that your pallet racking remains compliant, as well as significantly reducing the risk of an incident or racking collapse event that would likely result in a major loss of product, damage to the work environment, or worse, serious worker injury or a fatality.

SafeWork NSW has issued a Pallet Racking Fact Sheet which provides further guidance and advice, particularly around the racking design and layout, and for the specific consideration of the size, shape and weight of the products being stored.

Please contact QRMC for more information or assistance.